The facility management landscape across the GCC region is experiencing unprecedented transformation, driven by ambitious national visions, rapid urbanisation and the proliferation of smart building technologies. The GCC facility management market, valued at USD 60.11 billion in 2025, is projected to reach USD 77.52 billion by 2030, growing at a compound annual growth rate of 5.22 percent. For facility managers and operations leads tasked with maintaining complex portfolios across multiple sites, this growth presents both significant opportunities and formidable challenges.

At the heart of this transformation lies a critical technology enabler: Computerised Maintenance Management Systems (CMMS). These sophisticated platforms have evolved far beyond simple work order tracking to become comprehensive facilities management ecosystems that drive efficiency, reduce costs and enable the data-driven decision-making essential for competitive advantage in today’s dynamic market.

Whether you’re managing commercial real estate in Dubai, healthcare facilities in Riyadh, hospitality operations in Doha or industrial complexes across the broader GCC region, understanding how to select, implement and maximise the value of CMMS solutions has become essential to operational excellence. This comprehensive guide provides facility managers and operations leads with the insights needed to navigate the CMMS landscape and transform maintenance operations across your organisation.

Understanding CMMS: More Than Maintenance Software

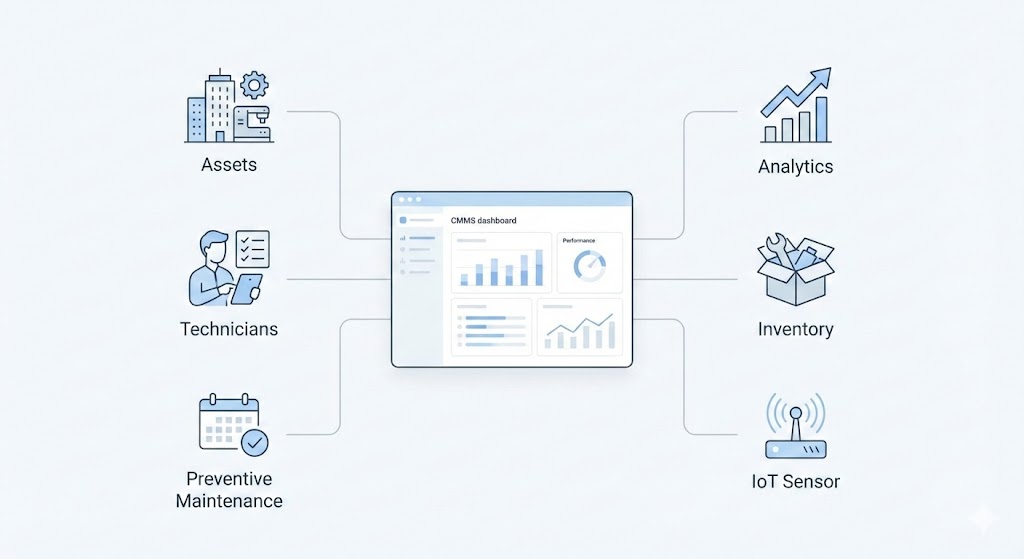

A Computerised Maintenance Management System is a software platform designed to streamline and optimise maintenance operations by centralising asset information, automating workflows and providing visibility into facility performance. Modern CMMS solutions represent a significant evolution from their predecessors, incorporating advanced capabilities including predictive analytics, mobile accessibility and integration with Internet of Things (IoT) sensors.

For GCC facility managers, CMMS platforms address several critical operational needs. They provide centralised visibility across distributed facility portfolios, enable standardised processes that reduce dependency on individual expertise and generate the documentation required for regulatory compliance and certification programmes prevalent throughout the region.

The distinction between CMMS and related technologies such as Enterprise Asset Management (EAM) or Computer-Aided Facility Management (CAFM) systems has blurred considerably in recent years. Whilst EAM typically encompasses broader asset lifecycle management across industrial environments, CMMS focuses specifically on maintenance operations and is particularly well-suited to facility management applications. Many modern platforms now offer integrated capabilities that span traditional boundaries, providing comprehensive facility management ecosystems rather than point solutions.

Understanding these distinctions helps facility managers evaluate solutions appropriately and avoid either over-investing in unnecessary capabilities or selecting platforms that lack essential functionality for their specific operational requirements.

The Business Case for CMMS in GCC Facilities

Facility managers seeking approval for CMMS investments must build compelling business cases that resonate with financial stakeholders. Fortunately, the return on investment data for well-implemented CMMS solutions is substantial and well-documented.

Research indicates that organisations implementing CMMS solutions achieve an average ROI of 450 percent within the first five years. More immediately, organisations using CMMS software experience a 28 percent reduction in maintenance costs and a 20 percent increase in equipment uptime. These figures translate directly to bottom-line impact in asset-intensive facilities across the GCC.

The sources of CMMS value extend across multiple dimensions. Direct cost reductions emerge from decreased materials costs—studies show material costs decline by 19 percent and inventory control costs by 18 percent following implementation. Labour productivity improvements result from streamlined work order management and reduced time spent searching for information. Companies using mobile CMMS solutions experience a 30 percent increase in technician productivity.

Asset lifecycle benefits represent another significant value driver. By facilitating regular maintenance and timely repairs, CMMS systems extend asset lifespan by 15 to 20 percent, deferring substantial capital expenditures. In the GCC’s harsh operating environments where equipment faces accelerated wear, these lifecycle extensions deliver particularly strong returns.

Operational efficiency gains manifest through reduced downtime, with organisations achieving an average 5 percent reduction in outage time. In facilities where downtime directly impacts revenue—such as hospitality, healthcare or retail operations—these improvements translate to substantial financial benefits beyond maintenance budget savings.

Risk mitigation and compliance benefits, whilst harder to quantify, provide real value. CMMS platforms automate documentation for regulatory requirements, reduce compliance violations and associated fines, and provide the audit trails essential for certification programmes. In sectors such as healthcare, food service and facilities management where regulatory compliance is stringent, these capabilities alone can justify investment.

For comprehensive resources on calculating your specific CMMS ROI and building stakeholder-ready business cases tailored to your facility portfolio, visit our resources section where we provide detailed calculators and industry benchmarks relevant to GCC operations.

Key CMMS Capabilities for GCC Facility Management

Modern CMMS platforms offer extensive functionality designed to address the full spectrum of facility management needs. Understanding these capabilities helps facility managers identify which features deliver the greatest value for their specific operational contexts.

Work Order Management

At its core, CMMS provides systematic work order creation, assignment, tracking and completion documentation. This seemingly basic capability transforms maintenance operations by eliminating paper-based processes, preventing tasks from falling through cracks and providing complete visibility into maintenance activities across all facilities and shifts.

Advanced work order management includes automated routing based on technician skills and availability, priority-based scheduling that ensures critical issues receive immediate attention, and comprehensive documentation that captures labour hours, parts consumed and corrective actions taken for every maintenance event.

Preventive Maintenance Scheduling

Preventive maintenance represents one of the most significant value drivers in CMMS implementations. Companies can save between 12 and 18 percent of costs typically associated with repairs and corrective maintenance by implementing preventive maintenance programmes. CMMS automates preventive maintenance by triggering work orders based on calendar schedules, usage meters or conditional triggers.

The platform maintains equipment-specific preventive maintenance procedures, ensures tasks are performed at optimal intervals and provides compliance documentation for required safety checks and regulatory inspections. For facility managers juggling preventive maintenance across hundreds or thousands of assets, this automation is transformative.

Asset Management and Equipment Histories

CMMS creates comprehensive asset registries that track equipment specifications, locations, warranties, service histories and associated documentation. This centralised repository ensures critical information is accessible regardless of staff turnover and supports informed decisions about repairs versus replacements.

Equipment history tracking reveals patterns that inform maintenance strategies. If specific assets require frequent repairs, managers can identify whether operational issues, environmental factors or equipment quality problems are driving elevated maintenance costs and take appropriate corrective action.

Mobile Accessibility for Technicians

The shift towards mobile-first CMMS platforms has dramatically improved technician productivity and data accuracy. Field technicians access work orders on smartphones or tablets, view equipment documentation and procedures, update task status in real-time and capture photos or notes directly from the field.

This eliminates delays associated with paper-based processes, improves data quality by capturing information at the point of service and enables immediate escalation of critical issues. For distributed facility portfolios common across the GCC, mobile capabilities are increasingly essential rather than optional.

Inventory and Parts Management

Effective spare parts management balances parts availability against inventory carrying costs. CMMS optimises this balance by tracking parts consumption, automating reorder triggers, managing supplier relationships and providing visibility into inventory across multiple locations.

For organisations managing facilities across multiple GCC countries, CMMS enables parts sharing to reduce overall inventory requirements whilst ensuring critical components are available when needed. The platform also tracks parts costs, supporting better procurement decisions and budget forecasting.

Analytics, Reporting and Business Intelligence

Data-driven decision-making separates high-performing facility operations from their peers. Modern CMMS platforms provide comprehensive analytics covering key performance indicators such as mean time between failures, mean time to repair, preventive maintenance compliance, technician productivity and cost per square metre.

Advanced platforms incorporate predictive analytics that identify patterns indicating potential equipment failures, enabling proactive intervention before problems escalate. Dashboard visualisations provide at-a-glance operational visibility for different stakeholder groups, from technicians needing daily task lists to executives monitoring portfolio-wide performance.

Industry-Specific CMMS Applications Across the GCC

The GCC’s diverse economic base means CMMS requirements vary significantly across industries. Understanding these sector-specific applications helps facility managers identify capabilities most relevant to their operations.

Commercial Real Estate and Mixed-Use Developments

The GCC’s impressive portfolio of commercial real estate, from Dubai’s iconic towers to Riyadh’s expanding business districts, requires sophisticated facilities management. CMMS helps property managers maintain HVAC systems, elevators, emergency power systems and building automation whilst managing tenant services and ensuring occupant satisfaction.

For mixed-use developments incorporating retail, residential and commercial spaces, CMMS provides the workflow management and reporting needed to coordinate maintenance across diverse facility types with varying stakeholder requirements and service level agreements.

Hospitality and Tourism Facilities

The region’s thriving hospitality sector demands exceptional facility reliability to support guest experiences. CMMS enables preventive maintenance that minimises guest-facing disruptions, tracks assets from furniture to kitchen equipment, manages contractor relationships for specialised services and ensures compliance with health and safety regulations.

Mobile CMMS capabilities are particularly valuable in hospitality environments where maintenance teams must respond immediately to guest requests whilst documenting all work for quality assurance and regulatory compliance.

Healthcare Facilities

Hospitals and medical centres rely on critical assets including diagnostic equipment, life support systems, HVAC and emergency power systems where downtime can directly impact patient outcomes. CMMS helps healthcare facilities prioritise maintenance based on equipment criticality, manage the specialised requirements of medical devices, maintain regulatory compliance and track total cost of ownership for capital planning.

The healthcare segment is expected to grow at the highest compound annual growth rate across GCC facility management markets, reflecting both healthcare expansion under national development programmes and increasing regulatory requirements driving CMMS adoption.

Industrial and Manufacturing Facilities

Manufacturing operations throughout the GCC require CMMS capabilities that bridge facility maintenance with production equipment management. Integration with Manufacturing Execution Systems (MES) provides comprehensive visibility from asset health through production output.

Preventive maintenance scheduling must coordinate with production schedules to minimise impacts, whilst spare parts management becomes critical for maintaining continuous operations. Predictive maintenance capabilities deliver particularly strong returns in manufacturing environments where equipment failures create cascading production impacts.

Government and Institutional Facilities

Government entities across the GCC manage extensive facility portfolios including offices, cultural facilities, educational institutions and public infrastructure. CMMS supports the standardisation, transparency and accountability requirements inherent in public sector operations.

Comprehensive audit trails document all maintenance activities, budget tracking capabilities support appropriations compliance and reporting functions provide the transparency required for governance and public accountability.

Selecting the Right CMMS Solution for Your Organisation

The GCC market offers numerous CMMS vendors ranging from global enterprise platforms to regional specialists and emerging cloud-native solutions. Facility managers must evaluate options carefully to identify the best fit for their organisations’ needs, resources and constraints.

Functional Requirements Assessment

Begin by documenting your specific functional requirements across work order management, preventive maintenance, asset tracking, reporting, mobile access and integration needs. Involve stakeholders from maintenance teams, operations, IT and finance to ensure requirements reflect actual operational needs rather than theoretical best practices.

Prioritise requirements into must-have capabilities that are non-negotiable, should-have features that deliver significant value and nice-to-have enhancements that would be beneficial but aren’t critical. This prioritisation focuses evaluation on solutions that meet essential needs whilst avoiding feature bloat that increases costs without delivering proportional value.

Technology Architecture Considerations

Cloud-based versus on-premise deployment represents a fundamental architectural decision. Cloud CMMS offers advantages including lower upfront costs, easier updates, anywhere access and scalability without infrastructure investments. These benefits make cloud deployment particularly attractive for organisations managing distributed facilities across the GCC.

On-premise solutions may be preferred by organisations with specific data sovereignty requirements, existing infrastructure investments or IT policies favouring local hosting. Understanding your organisation’s technology strategy and constraints guides this decision appropriately.

Mobile functionality has shifted from optional to essential. Evaluate mobile applications for ease of use, offline capability (critical in areas with intermittent connectivity) and functionality completeness. Technicians should be able to perform all essential tasks from mobile devices without needing desktop access.

Integration and Ecosystem Compatibility

CMMS must integrate with your existing technology ecosystem. Evaluate integration capabilities with your ERP system for procurement and financial data, BMS for building systems monitoring, IoT platforms for sensor data and any industry-specific systems relevant to your operations.

Modern platforms offer RESTful APIs that enable custom integrations, but pre-built connectors for common systems reduce implementation time and ongoing maintenance burden. Verify that integration capabilities align with your current systems and anticipated technology roadmap.

Vendor Considerations for GCC Operations

Vendor presence and support capabilities in the GCC region warrant careful evaluation. Local implementation partners, regional support resources and ongoing development commitment to the region all impact long-term success.

Verify that the solution supports Arabic language interfaces where required, accommodates regional date formats and holidays, and provides documentation and training materials appropriate for your workforce. These localisation factors significantly impact user adoption.

Reference customers in similar industries and similar facility types provide valuable insights into real-world performance. Request references and conduct thorough reference checks focusing on implementation experience, ongoing support quality and actual ROI achieved.

Total Cost of Ownership Analysis

Beyond licence fees, consider implementation costs including software configuration, data migration, integration development and staff training. Ongoing costs include annual maintenance and support fees, infrastructure hosting (for on-premise solutions), staffing for system administration and periodic upgrades.

Organisations implementing CMMS solutions see returns that far exceed costs when properly implemented, but accurate total cost of ownership calculation is essential for budgeting and realistic ROI projections. Most successful implementations achieve 300 to 500 percent returns within 18 to 24 months through comprehensive strategies balancing cost reduction with reliability improvement.

At WMS, we help GCC organisations navigate CMMS selection through structured needs assessment, vendor evaluation and implementation planning. Our experience across Middle East facilities enables us to identify solutions that deliver real-world results in regional operating environments. Contact our team to discuss your CMMS requirements and explore how we can support your facility management transformation.

Implementation Best Practices for GCC Facilities

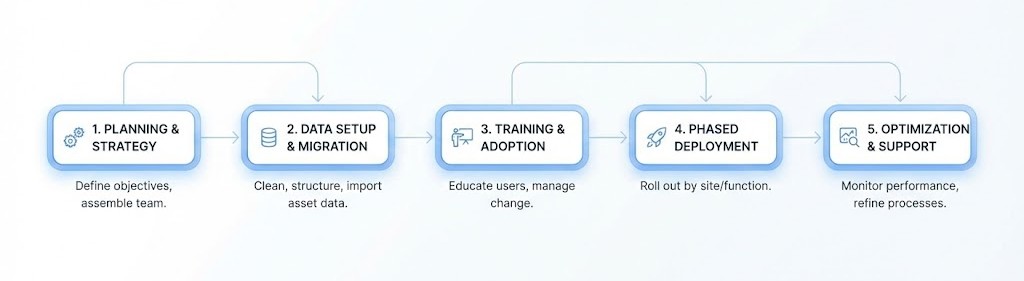

Successful CMMS implementation requires more than selecting the right software—it demands careful planning, stakeholder engagement and attention to organisational change management. These best practices help ensure your CMMS initiative delivers expected returns.

Establish Clear Objectives and Success Metrics

Define what success looks like before beginning implementation. Whether your priorities are reducing maintenance costs, improving equipment uptime, achieving regulatory compliance or improving technician productivity, establish baseline measurements and targets.

These metrics guide implementation decisions, help prioritise feature deployment and enable you to demonstrate ROI to stakeholders. Without clear objectives, implementations risk becoming technology projects disconnected from business outcomes.

Invest in Data Quality and Asset Information

CMMS effectiveness depends fundamentally on data quality. Dedicate time to creating accurate asset registries, documenting equipment specifications and capturing maintenance histories. This foundation supports all other CMMS capabilities and is essential for generating reliable analytics.

Asset hierarchies that reflect your facility structure and operational organisation make the system intuitive for users and support meaningful reporting. Invest the effort required to get data structure right from the beginning rather than attempting corrections after go-live.

Prioritise User Adoption and Change Management

Resistance from maintenance teams can derail even technically sound implementations. Involve technicians and supervisors early in the process, incorporate their feedback into system configuration and provide comprehensive training that goes beyond system mechanics to explain how CMMS benefits their daily work.

Champions within maintenance teams who actively use and promote the system accelerate broader adoption. Identify and empower these champions, providing them with additional training and recognition that reinforces their advocacy.

Implement in Phases with Quick Wins

Rather than attempting to deploy all CMMS capabilities across all facilities simultaneously, consider a phased approach. Start with core work order management and preventive maintenance at a pilot site, demonstrate success and then expand functionality and coverage.

This approach reduces risk, enables learning from early challenges and provides quick wins that build momentum and stakeholder confidence. Celebrate and communicate early successes to reinforce that the investment is delivering tangible value.

Leverage Cloud and Mobile-First Design

Modern CMMS platforms designed mobile-first rather than desktop-first with mobile added later provide superior technician experiences. Evaluate mobile applications thoroughly during selection and ensure mobile workflows are emphasised during implementation.

Cloud deployment offers particular advantages for organisations managing facilities across multiple GCC countries, providing consistent access regardless of location whilst avoiding the infrastructure complexity of hosting systems locally in each country.

Plan for Integration from the Beginning

CMMS integration with ERP, BMS and other systems delivers significant value but requires planning from project inception. Define integration requirements early, allocate appropriate time and resources and involve IT teams in integration planning and execution.

Well-integrated systems eliminate duplicate data entry, provide comprehensive visibility and enable automated workflows that span multiple platforms. Organisations implementing CMMS in isolation miss substantial portions of potential value.

Regional Considerations for GCC CMMS Implementation

Facility managers in the GCC face unique considerations that influence CMMS implementation approaches and priorities.

Harsh Environmental Conditions

The extreme heat, humidity and sand prevalent across much of the GCC accelerate equipment wear and increase maintenance requirements. CMMS preventive maintenance capabilities become particularly critical for tracking equipment performance in harsh conditions and adjusting maintenance frequencies based on environmental impact.

Condition-based maintenance triggers that account for operating conditions help optimise maintenance timing. Equipment operating in extreme heat may require service more frequently than manufacturer recommendations based on standard operating conditions.

Multi-Country Operations and Regulatory Complexity

Organisations managing facilities across multiple GCC countries must navigate varying regulatory requirements, labour practices and cultural contexts. CMMS platforms that support multiple languages, accommodate country-specific compliance workflows and provide flexible reporting help manage this complexity.

Centralised visibility across countries enables sharing of best practices whilst maintaining local operational autonomy appropriate to each market’s requirements.

Labour Force Considerations

The GCC’s dynamic labour market, with significant expatriate workforces and ongoing nationalisation initiatives, creates challenges for maintaining institutional knowledge. CMMS captures and preserves knowledge through standardised procedures, maintenance histories and troubleshooting guides that reduce dependency on individual expertise.

Training capabilities within CMMS platforms support efficient onboarding of new technicians, reducing the productivity impacts of workforce changes.

Infrastructure Development and Growth

The region’s ambitious infrastructure development programmes under Vision 2030 initiatives and similar national plans create both opportunities and challenges for facility managers. CMMS platforms that scale efficiently support facility portfolio growth without requiring platform replacement or major reconfigurations.

Cloud-based solutions offer particular scalability advantages, adding new facilities without infrastructure investments or capacity concerns.

The Future of CMMS in GCC Facility Management

The CMMS landscape continues evolving rapidly, with several emerging trends that will shape facility management across the GCC in coming years.

Artificial Intelligence and Predictive Maintenance

AI-powered predictive maintenance capabilities are moving from detecting patterns in historical data to prescribing specific maintenance actions and autonomously scheduling work. Machine learning algorithms continuously improve prediction accuracy, learning from every maintenance event and equipment failure.

For GCC facilities operating in extreme conditions where equipment failures can escalate rapidly, predictive capabilities that provide advance warning of potential problems deliver exceptional value by enabling proactive intervention before minor issues become major failures.

Internet of Things Integration

The proliferation of IoT sensors throughout buildings enables real-time monitoring of equipment health, environmental conditions and energy consumption. CMMS platforms increasingly serve as central hubs that collect IoT data, apply analytics and trigger automated maintenance workflows.

Saudi Arabia’s facility management market is experiencing tech-driven transformation through rapid integration of IoT devices and sensors within buildings to gather real-time data on energy consumption, occupancy rates and equipment performance. This trend is accelerating across the broader GCC region.

Augmented Reality for Maintenance

Augmented reality applications overlay maintenance instructions, parts identification and troubleshooting guidance onto technicians’ views of equipment through smart glasses or mobile devices. This technology accelerates training, reduces errors and enables remote expertise where senior technicians can guide less experienced colleagues through complex procedures.

Sustainability and Energy Management

As environmental considerations become more important throughout the GCC—driven by green building certifications, energy efficiency mandates and corporate sustainability commitments—CMMS platforms increasingly incorporate sustainability metrics tracking carbon footprints, energy consumption and circular economy opportunities.

Integration between CMMS and building energy management systems enables maintenance activities that optimise both asset reliability and energy efficiency, supporting both operational and sustainability objectives.

For insights on how emerging technologies are transforming facility management across the Middle East and resources on preparing your organisation for these developments, explore additional content on WMS’s platform.

Conclusion: Transforming GCC Facility Management Through CMMS

For facility managers and operations leads across the GCC region, the imperative is clear: the complexity of modern facility management, the financial pressures to reduce costs whilst maintaining service levels, and the technical capabilities available through modern CMMS platforms combine to make this technology essential rather than optional.

The business case is compelling, with documented ROI ranging from 300 to 500 percent within 18 to 24 months for well-implemented solutions. The GCC facility management market’s projected growth to USD 77.52 billion by 2030 reflects both increasing outsourcing of facility services and growing technology adoption including CMMS platforms.

Success requires more than software procurement—it demands careful solution selection aligned to your specific operational requirements, structured implementation that prioritises user adoption and data quality, and ongoing optimisation that evolves CMMS capabilities as your organisation grows and technology advances.

Whether you’re managing commercial real estate, hospitality facilities, healthcare operations, industrial complexes or government infrastructure across the GCC, CMMS provides the platform for transforming maintenance from a cost centre focused on keeping assets running to a strategic capability that optimises asset value, reduces total cost of ownership and enables the operational excellence essential for competitive advantage.

The journey toward CMMS-enabled facility management begins with understanding current challenges, defining clear objectives and selecting the right platform for your organisation. The returns—measured in reduced maintenance costs, improved equipment reliability, extended asset lifecycles and enhanced operational visibility—justify the investment many times over.

Ready to transform your facility management capabilities and position your organisation for the future? The team at WMS brings extensive experience implementing CMMS solutions across GCC facilities, ensuring solutions work in real-world conditions whilst delivering measurable business results. We understand the regional operating environment, regulatory requirements and cultural considerations that impact implementation success.

Don’t let outdated maintenance processes continue limiting your operational performance. Take the first step toward data-driven, efficient facility management that maximises asset value and supports your organisation’s growth objectives. Your facility portfolio represents substantial capital investment—ensure you’re protecting and optimising that investment through comprehensive CMMS capabilities.

Frequently Asked Questions (FAQs)

What is a CMMS and how does it support facility management in the GCC?

A Computerised Maintenance Management System (CMMS) is software designed to streamline maintenance operations by managing work orders, assets, preventive maintenance schedules and reporting. In the GCC, CMMS helps facility managers improve uptime, reduce costs and maintain compliance across distributed portfolios.

Why is CMMS important for GCC facility managers?

GCC facilities operate in harsh environmental conditions including extreme heat and humidity. CMMS enables preventive maintenance, improves asset lifespan and provides real-time operational visibility, which is essential for reducing downtime and maintaining service standards.

What ROI can GCC organisations expect from CMMS implementation?

Organisations typically achieve 300%–500% ROI within 18–24 months. Benefits include reduced maintenance costs (up to 28%), improved equipment uptime (20% increase) and higher technician productivity through mobile-enabled workflows.

What is the difference between CMMS and EAM systems?

CMMS focuses primarily on maintenance management and facility operations, while Enterprise Asset Management (EAM) covers the entire asset lifecycle including procurement, capital planning and disposal. Many modern platforms combine both capabilities.

Is cloud-based CMMS better for GCC organisations?

Cloud-based CMMS is generally preferred in the GCC due to scalability, lower upfront costs, easier multi-site management and remote accessibility across UAE, Saudi Arabia, Qatar and other GCC countries.

Can CMMS integrate with ERP and IoT systems?

Yes. Modern CMMS platforms integrate with ERP systems for financial tracking, Building Management Systems (BMS), IoT sensors for real-time monitoring and HR systems for labour management, enabling a fully connected facility ecosystem.

What industries in the GCC benefit most from CMMS?

CMMS is widely used across:

Commercial real estate

Hospitality and tourism

Healthcare facilities

Manufacturing and industrial plants

Government and institutional buildings

How long does CMMS implementation take?

Implementation timelines vary depending on facility size and integration complexity. On average, GCC organisations can expect deployment within 3–6 months for standard implementations.

What are the key success factors for CMMS implementation in the GCC?

Successful CMMS projects require:

Clear objectives and KPIs

Accurate asset data

Strong user training and adoption

Mobile-first deployment

Integration planning from the beginning

Mahitab Maher

SAP professional specializing in SAP products, helping companies turn complex processes into smooth, scalable operations.

CMMS solutions

facility management GCC

maintenance management software

UAE facility operations

Saudi Arabia facilities

work order management

asset management

mobile CMMS

facility management software Middle East

preventive maintenance